Packaging Systems

We offer a wide range of bagging applications fit for a variety of different industries and production levels to help you increase the productivity of your production process.

High-performance bagging machines: accurate, fast and reliable

Our wide range of bagging machines enables us to provide solutions to many different industries: Mining, Building, Petrochemical, Chemical and Fertilizer Industries. Further, PAYPER is one of the important suppliers in the sectors of Food for Human Consumption, Animal Feed and Non-Food Crops. We have machinery for all kinds of bags: FFS, Open Mouth, Valve Bags and Big Bags.

TUBULAR FFS

A Form, Fill and Seal bagging machine is an integrated solution in a compact system. The bag is cut and formed from a continuous tubular reel of LDPE or laminated aluminium reel.

The Tubular FFS bag is an efficient solution for bagging all types of powder or granulates applied in the food industry, such as salt or sugar, etc. It is also used in the petrochemical, fertilizer and building materials industry amongst many other applications.

Valve Bags

Valve bags or self-closing bags have an infinite number of applications. Powdery products or even blends of powders and granulates can easily be packed in paper or plastic valve bags with de-aeration systems by means of PAYPER’s unique fluidization technology.

Granulates or any kind of free flowing products can be packed in valve bags by means of the gravity system. An ultra-sonic valve sealing system guarantees a tight, closed bag. It further ensures efficient protection of the product in the bags and avoids any product leakage.

Open Mouth Bag

The open mouth bag is a pre-made bag in paper, PE, PP, Aluminium or even combined PE and Paper. The open mouth bag technology presents good flexibility for all different sizes of bags, which may have to be packed on the same line.

Bags of different materials can be used on the same line, e.g. packing one batch in paper bags and the next in PE bags. Different types of bags may also be used, with or without gussets, block bottom, pinch bottom, etc. The wide range of bagging machines for open mouth bags starts with the semi-automatic line and ends up with the fully automatic version with capacity of up to 1,800 bags/hour.

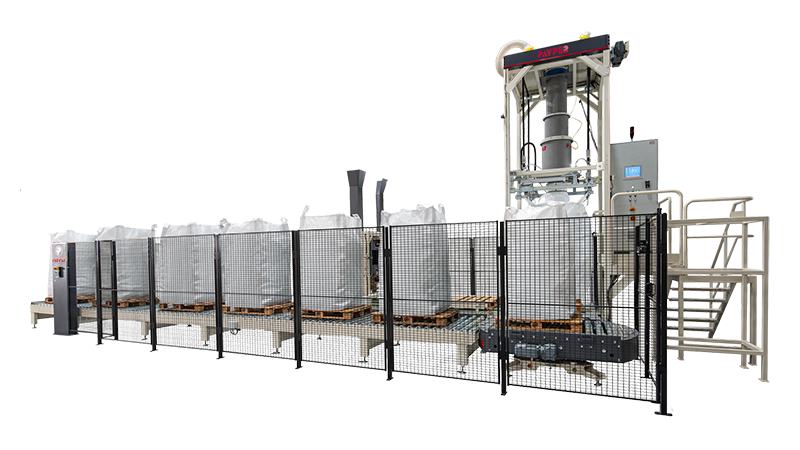

BIG BAG or FIBC and OCTABIN filling station

Our comprehensive range of filling stations is designed to cater to various bulk materials transportation and storage needs. These filling systems are perfectly suited for a wide selection of substances, including chemicals, plastic pellets, fertilizers, seeds, building materials, and food products.

That’s why we offer filling stations that are specifically tailored to handle Big Bags with 1, 2, or 4 straps. Depending on your preferences, these Big Bags can be easily managed with or without the use of a pallet. For maximum efficiency, our filling stations allow for the stacking of two Big Bags on top of each other, optimizing storage space and streamlining operations.

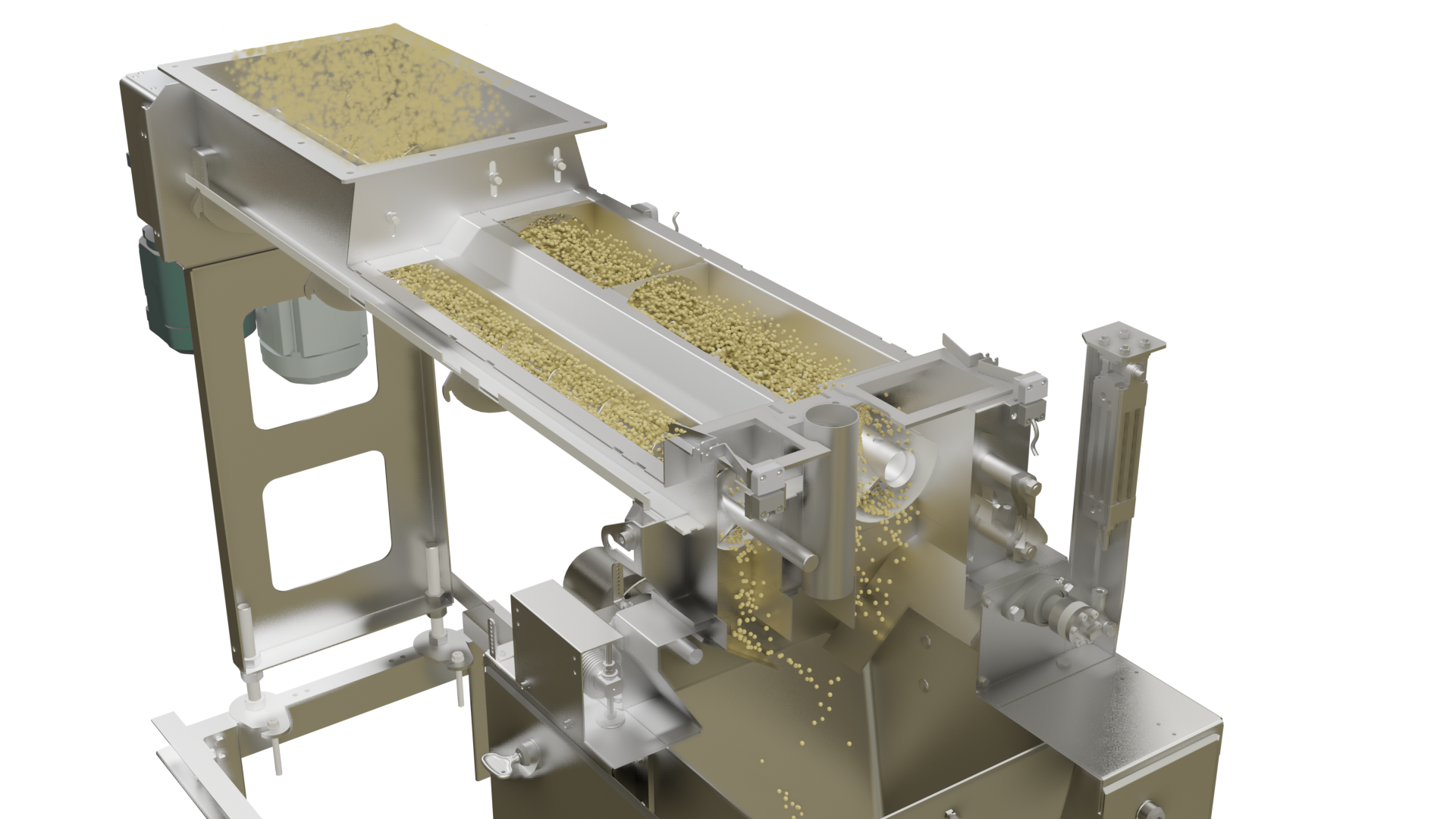

Dosing and weighing

We offer a comprehensive weighing and dosing solution for all types of dry bulk materials, whether they are free-flowing or not, including powders, flakes, and granulates.

No matter the nature of the product, free-flowing or not, powdery, flakes or granulates, we can help you find the appropriate weighing & dosing solution.

Palletizing

Once bags are filled, closed and quality checked they have to be palletized before being transported to their destination. The quality of the palletization is a key issue for safe long-distance transport. We offer the right palletizer for all different needs.

Palletizers with a high infeed level are appropriate for bagging operations at fast speeds. At medium and high speeds, the conventional high-level infeed palletizer HLP is suited for Valve Bags or FFS bags. A high-level infeed palletizer with a gripper head, HLG, is also available. The low-level infeed palletizer LLG with gripper head is excellent for Open Mouth bags. The LLP low-level infeed palletizer with row-push function is intended for valve bags and FFS bags.