Feeding & Metering

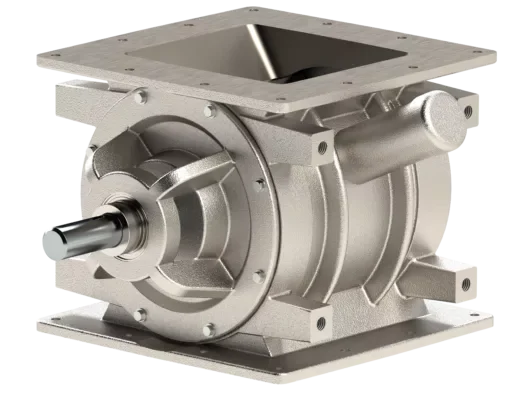

Features such as vent ports integrated to the rotary valve feeder housing, and standard, 8-vane rotors maximize the air flow path through the rotor pockets to improve material release. In bulk material feeding or metering applications, rotary feeders will improve throughput and reduce total energy consumption.

Eriez Vibratory Feeders & Conveyors

Eriez vibratory equipment effectively and efficiently conveys, screens and feeds materials in quantities ranging from a few spoonfuls to tons per hour.

Vibratory Screeners

High capacity Vibratory Screeners are designed for liquid/solid separation and wet or dry classification. These easy-to-operate gyratory units allow trouble-free and quick tuning to specific feed rates, product and separation requirements. Benefits are many, including long screen life and no damping under loads. Inline screeners are also available.

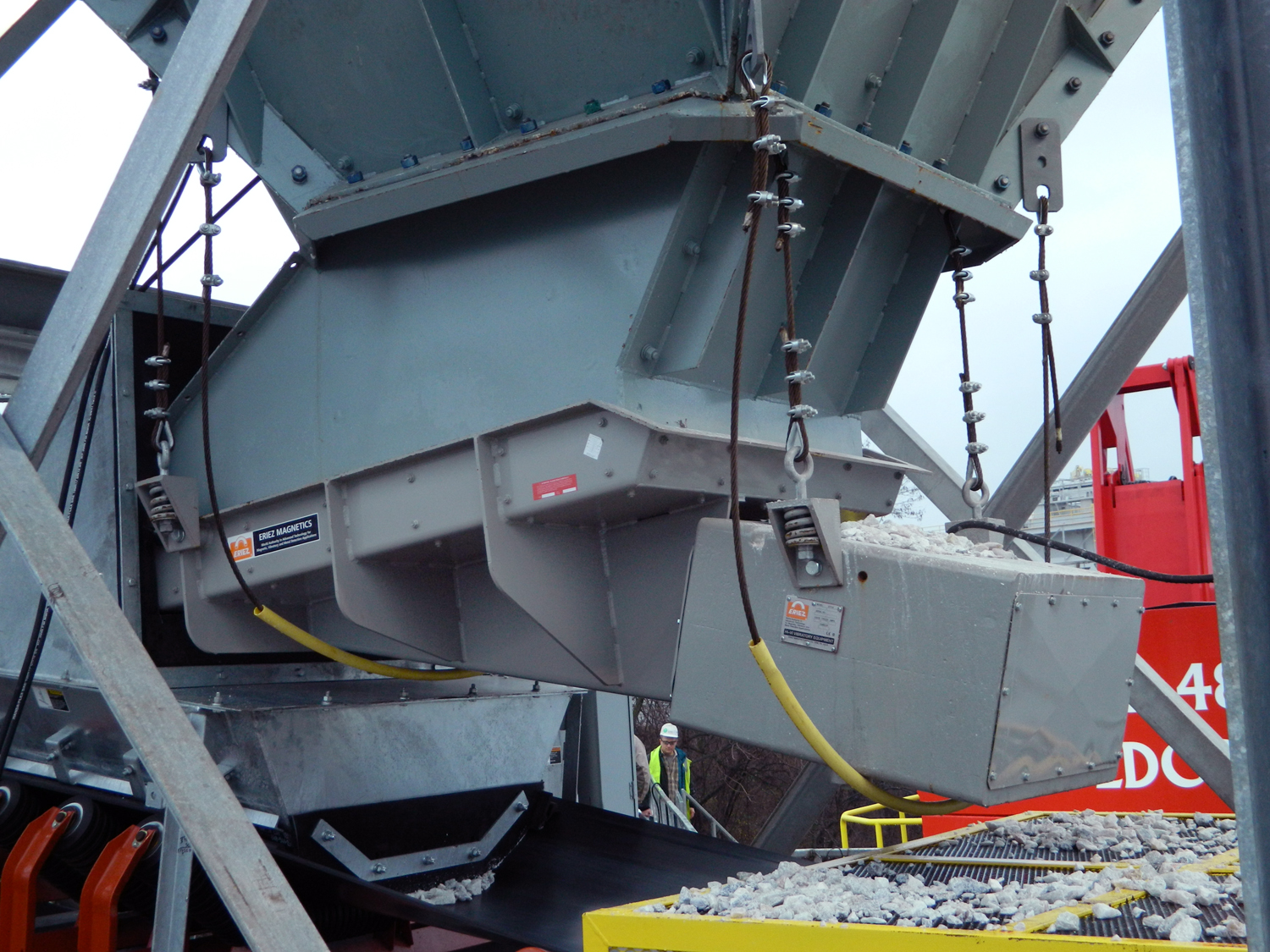

Heavy Duty Feeders

Our heavy duty line of Brute Force feeders provide a cost effective means to feed or screen large volumes of bulk material for applications where limited feed rate adjustability is required. Brute Force feeders are ideal for applications where limited feed rate adjustability is required. Brute Force feeders are ideal for applications such as coal or stone processing, recycling and scrap recovery. Eriez Brute Force feeders can be provided with unique tray designs for your specific applications.

Feeder tray motion is provided by eccentric weights mounted on synchronized, counter-rotation, twin motors. The motors counteract each other to minimize the isolation problems associated with single centric drive systems. Feed rate can be varied by adjusting the weights. The twin motor drives operate on standard AC power.

Light and Medium Duty Feeders

Eriez’ unique Hi-Vi magnetic drive circuit provides a simple yet powerful solution to difficult material feeding applications.

These feeders, with their totally enclosed magnetic drive, can feed practically any bulk material from micron size to bulky chunks. Solid-state controls operate the feeders with “watch–like” precision. In addition, you get all the features that for years have made Eriez Feeders the leaders in quality and dependability.

Eriez has standard models for the majority of feeding applications. Special units such as multiple drives, enclosed trays or screens can be designed for the best solution to your application. In addition, a wide variety of standard and special trays are available.

Vibratory Conveyors

Eriez mechanical feeders are simple, rugged, vibrating machines designed to handle a variety of bulk materials. The conveyors are available in single-mass and two-mass vibrating systems excited by a motor-driven eccentric shaft. Springs vary according to the type of application.

The remarkable compact, straight-line design of these conveyors presents an extremely low profile yet allows for ease of maintenance. Minimum headroom is required for installation.

Vibratory Controls

Designed to provide a precise amount of vibration for vibratory feeders, Eriez offers a line of solid state Feeder Controls with state-of-the-art electronics at competitive prices.

Bin Vibrators

Eriez Bin Vibrators are used in applications ranging from the tiniest hopper to huge bunkers, providing efficient and economical movement of hard-to-handle bulk materials.

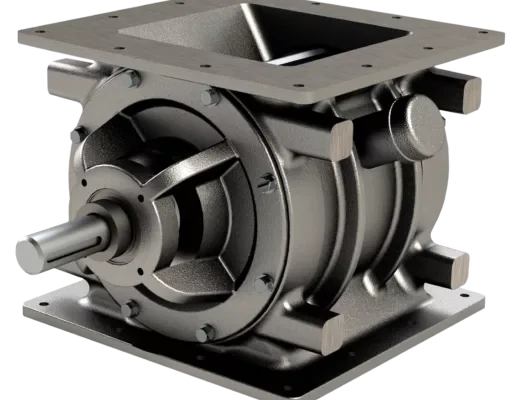

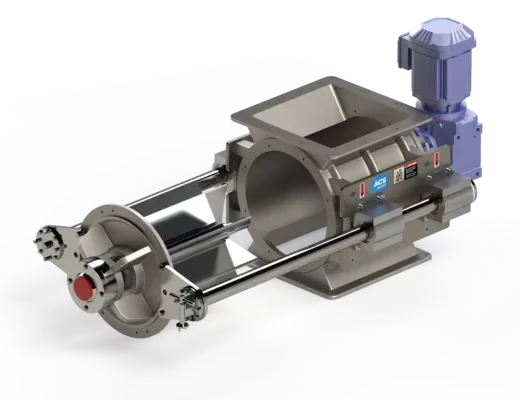

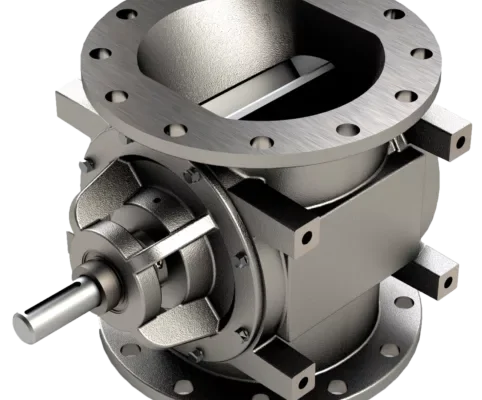

Rotary Airlock

A rotary airlock will immediately bring tangible operating advantages to a dry bulk material handling or dust collection application. The precision casting, CNC machining, and tight final assembly tolerances of our valves ensure minimal air leakage and low effective pressure drop between areas with different air pressures.

We can handle any kind of airlock, metering + feeding, or rotary application.

Convey-All™/FSC Flexible Screw Conveyor

Metalfab Convey-All/FSC Flexible Screw Conveyors feature a rugged modular design and provide a highly effective yet economical means to convey powder or granular material without product separation. Conveyors are available in configurations from 10 to 20 ft. lengths with a choice of a 3″ diameter helix screw rated to convey up to 150 cu. ft./hr. or a 4″ diameter helix screw rated to convey up to 450 cu. ft./hr. Engineered with only one moving part, the conveyors are economical to use, easy to clean, and simple to maintain with virtually no process downtime.

Features/Benefits

- Rugged, Flexible Design: provides long life and versatility to accommodate other Metalfab upstream and downstream equipment such as bin activators, bulk bag unloaders, Posibins™, feeders, and hoppers

- F9 Only One Moving Part: makes the conveyor economical to operate and easy to maintain with virtually no process downtime

- Top and Bottom Cleanout Ports: provide access flexibility in tight spaces and allow the conveyor to be easily cleaned

- Endless beaded Flexible Sleeve: is 7/16″ thick with 3-ply reinforcement that will not puncture, slip or leak

- Standard 304 SS Helix Screw and Contact Parts: permit use in a wide range of applications

- Dust-Free Connections: minimize housekeeping and permit use in any plant environment (sleeve and clamps optional)

- Optional Sanitary Design: available upon request

Operating Characteristics

- Handles powders, pellets, flakes, and other dry solids

- Two models in configurations from 10 to 20 ft. lengths

- 3″ diameter flat open-type helix screw with beveled edges conveys up to 10 cu. ft./hr. and 4″ diameter helix screw conveys up to 450 cu. ft./hr

- Ruggedly built for continuous, long lasting operation

Continuous Weigh Feeders

For highly accurate, gravimetric feeding of dry bulk materials in batch or continuous operation, our Continuous Weigh Feeders are designed to provide feeding in either batch or continuous mode depending upon the arrangement of the feeder’s control electronics.

- Accuracy: ±0.25% to ±0.5% on batch or on minute samples when continuous

- Features: Highly accurate gravimetric feeder utilizing platform and balance scale. Automated manual batching, 2 or 5 cu. ft. hopper. Sanitary construction available.

- Drive: AC variable frequency drive standard.

- Feed Rates: 0.03 to 550 cu. ft./hr.

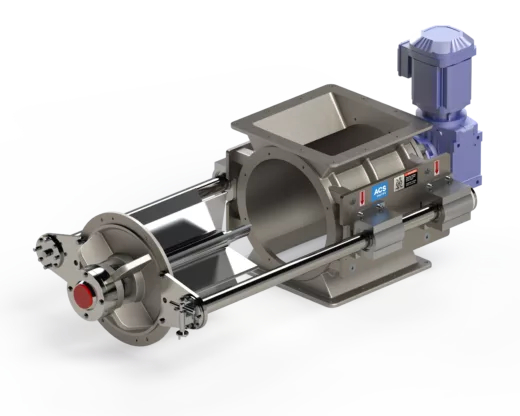

MetaTech™ Screw Feeders

Metalfab’s ruggedly built MetaTech Feeder features a compact, space-saving design, low maintenance direct drive, and new Delrin® bushing for highly accurate and dependable metering of powders, pellets, flakes, and agglomerates.

- Provides highly accurate, dependable metering of powders, pellets, flakes and agglomerates

- Ruggedly built for continuous, long-lasting operation

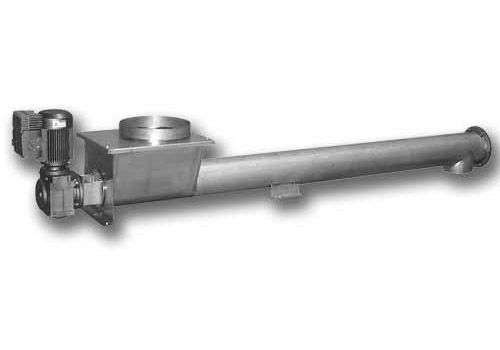

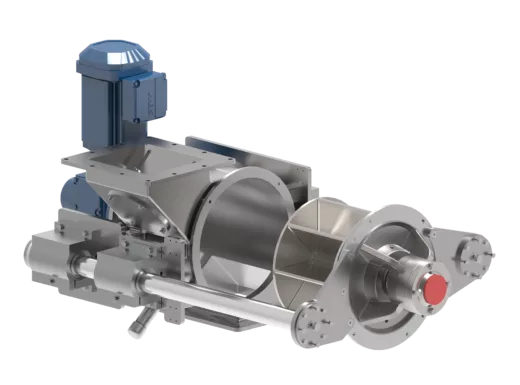

MTL Screw Feeder/Conveyor

Metalfab’s highly accurate, dependable Model MTL Volumetric Screw Feeder/Conveyor has only five moving parts – drive, coupling, two bearings, and a screw. The combination of a large inlet and a U-shaped trough help ensure complete filling of screw flights and provides feed accuracies of ±1 to 1-1/2%. When a Metalfab Posibin™ or Bin Activator is used to supply the feeder even greater accuracies may be obtained.

- Provides precise metering of dry materials in the chemical, food, plastics, pharmaceutical, and foundry industries

- Can also be used as a short distance conveyor with centerline of inlet to outlet dimensions of 35″ to 144″ depending on screw size